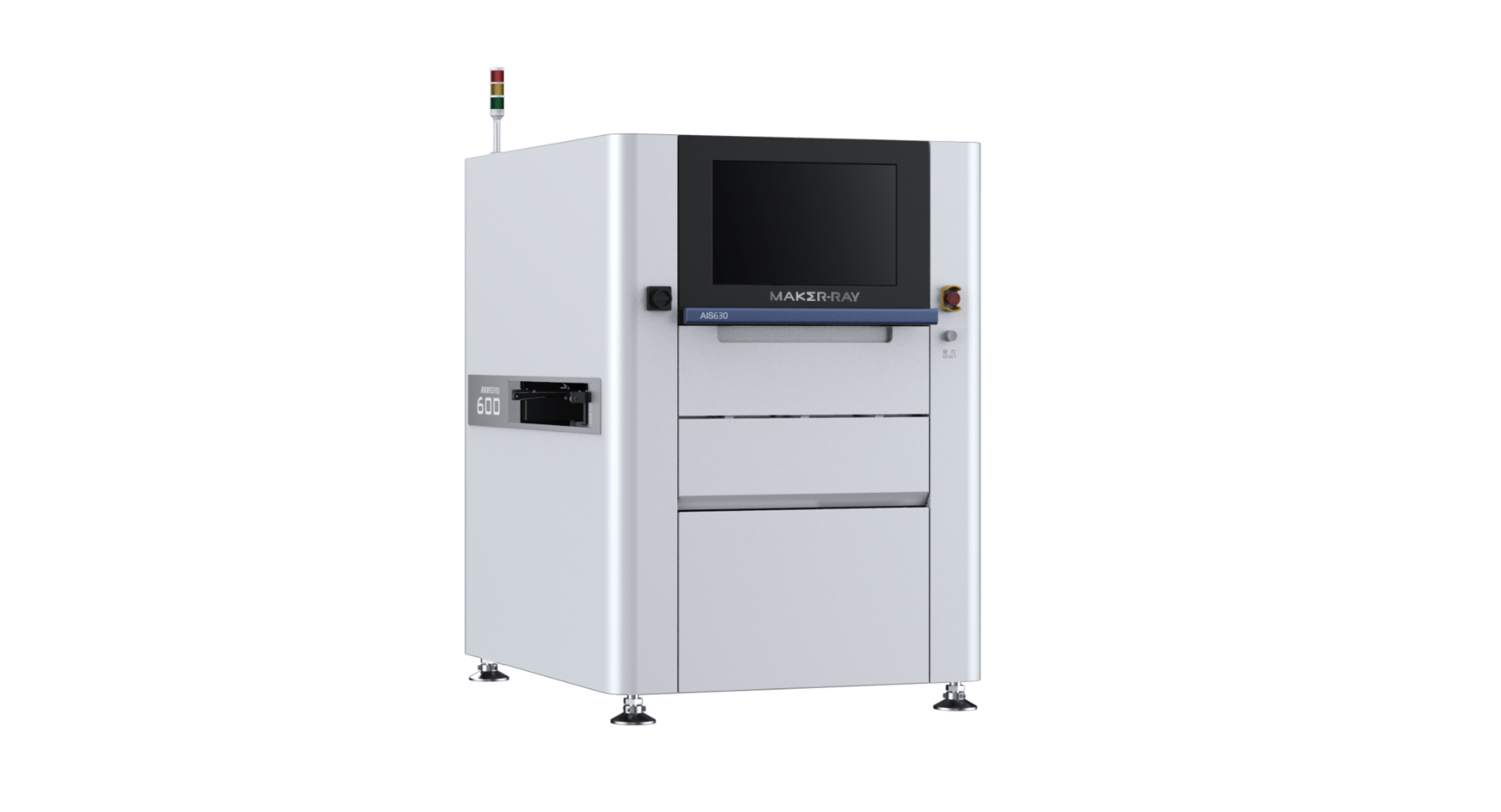

Inline PCBA solder paste inspection

AIS63X

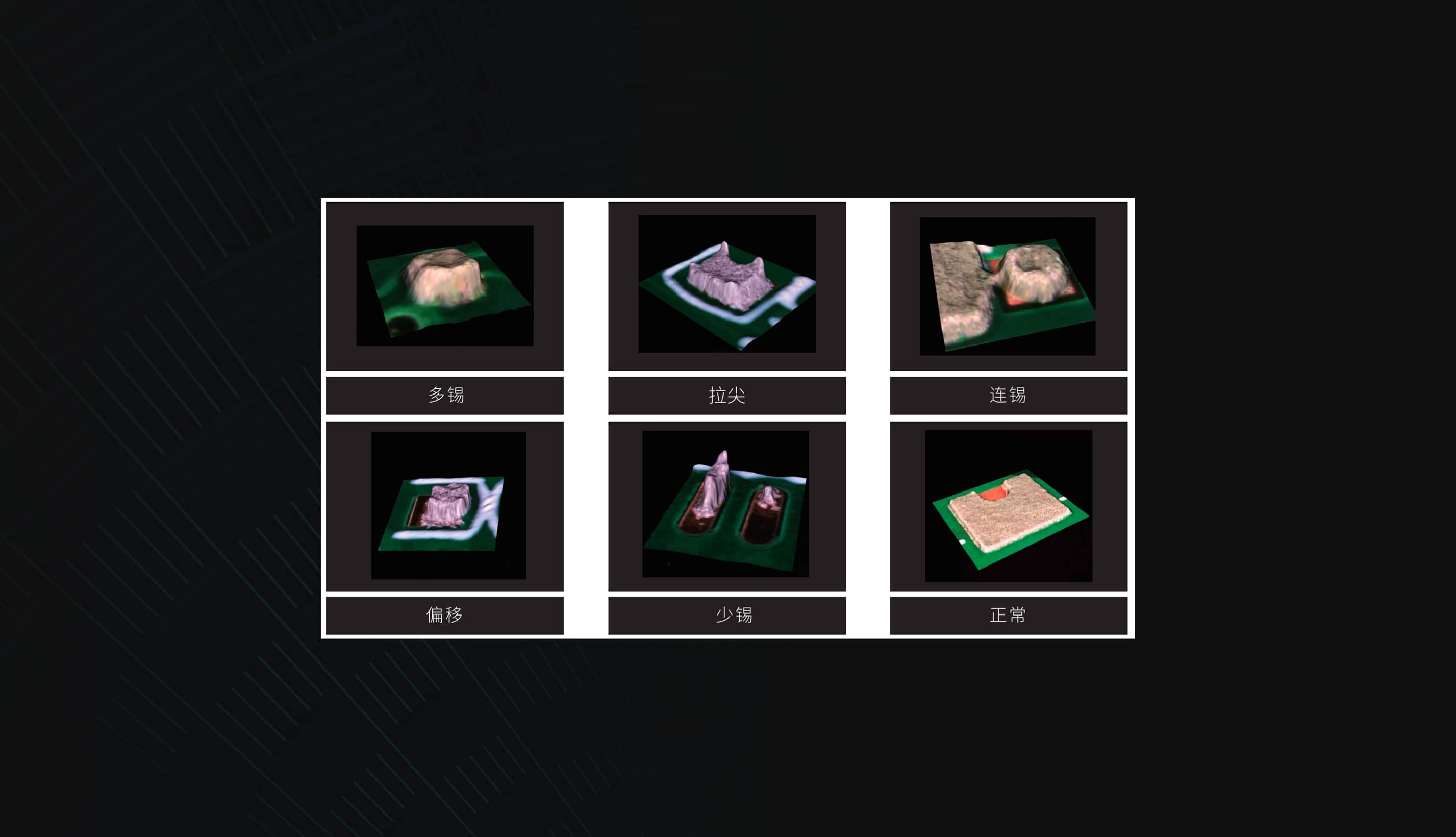

Stable detection of defects, improve production straight-through rate

Multi-directional structured light imaging generates high-precision 3D images

Fusion AI intelligent denoising, real restoration of solder paste imaging

Strong anti-interference, high detection, low false positives

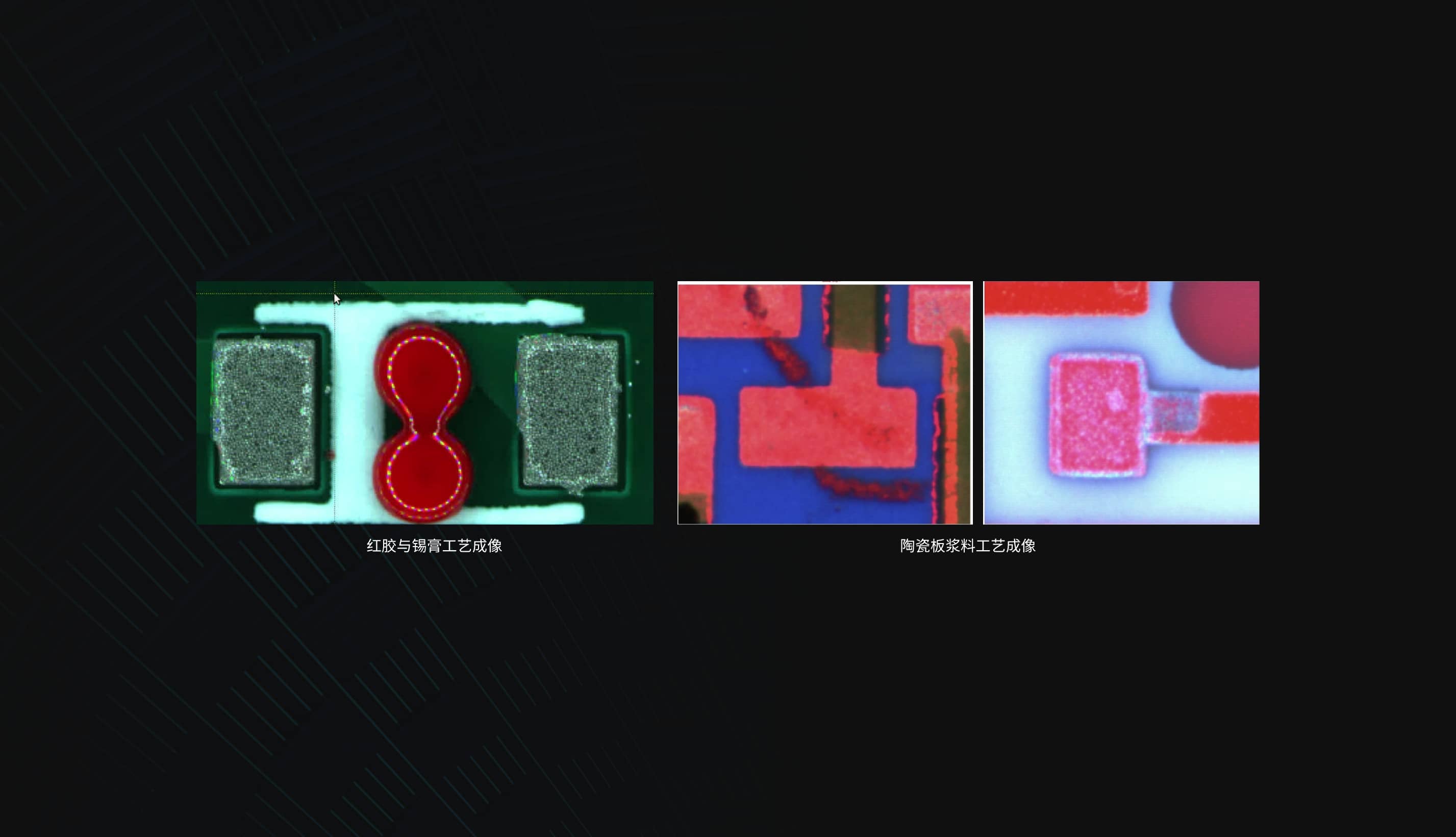

High precision imaging scheme, true restoration of solder paste imaging

AI intelligent denoising is integrated to restore the real and objective solder paste imaging. The specially developed light source scheme makes SPI adapt to the identification of PCB pads of different colors and materials, and improves the imaging accuracy.

Simple and easy to learn programming, programming efficiency is higher

AI intelligent programming, one click to generate the whole board image, intelligent configuration parameters, does not rely on engineer experience, higher program consistency.

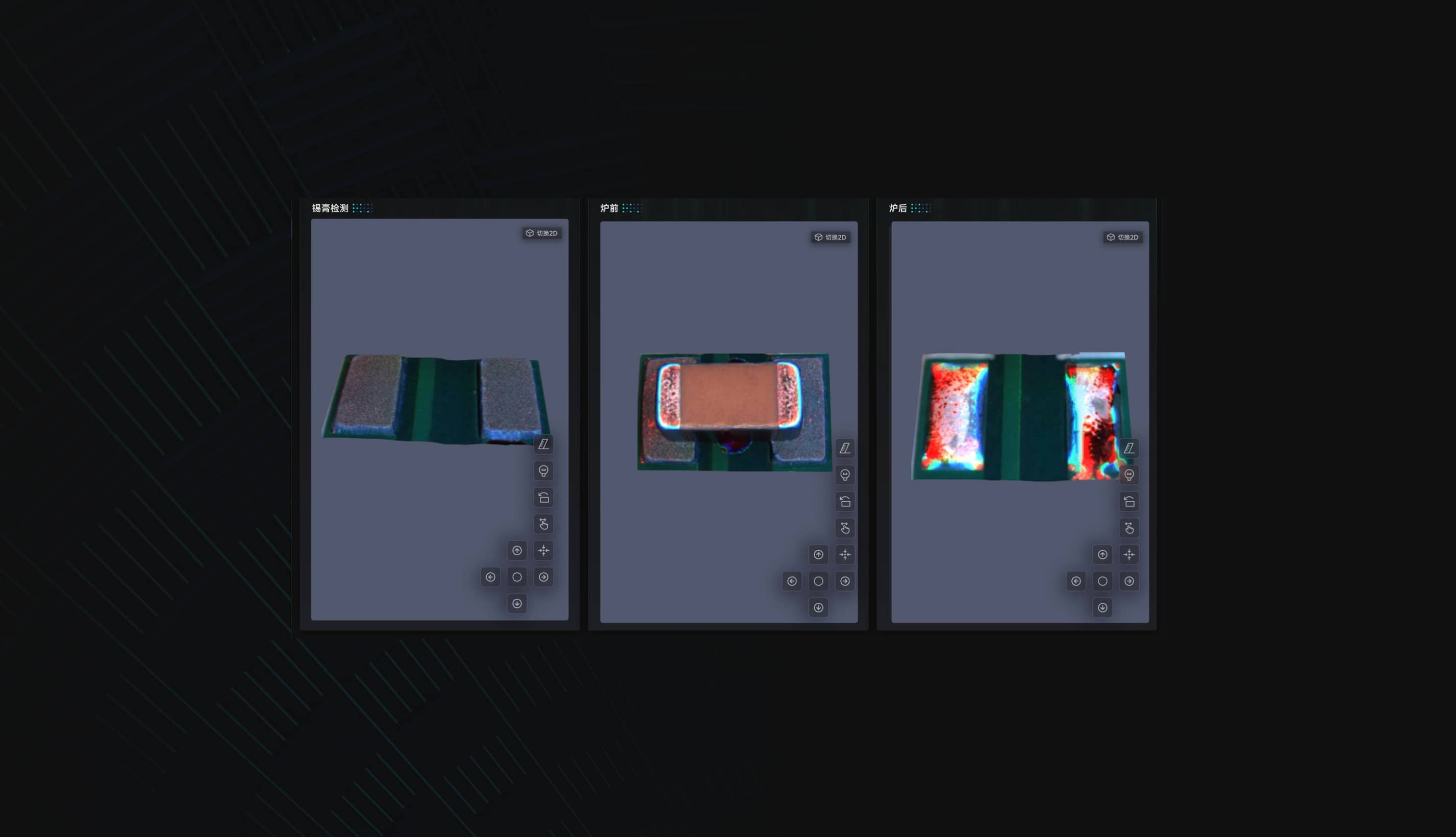

Three-point lighting, assist to quickly locate abnormal causes

Integrate the inspection data of SPI, pre-furnace AOI and post-furnace AOI, quickly analyze product defects, locate the root cause, and help engineers develop targeted improvement measures to improve the situation of defective products and increase the yield of good products in the production line.

Inspection case

Specification