Proofing

"AI+AOI". Extremely Simple Intelligent Programming, Unleashing Productivity

Industry pain points

High mix and low volume require high programming efficiency.

In high-mix, low-volume industries, traditional AOI needs to be programmed every time the model changes, which causes higher workload and inefficiency.

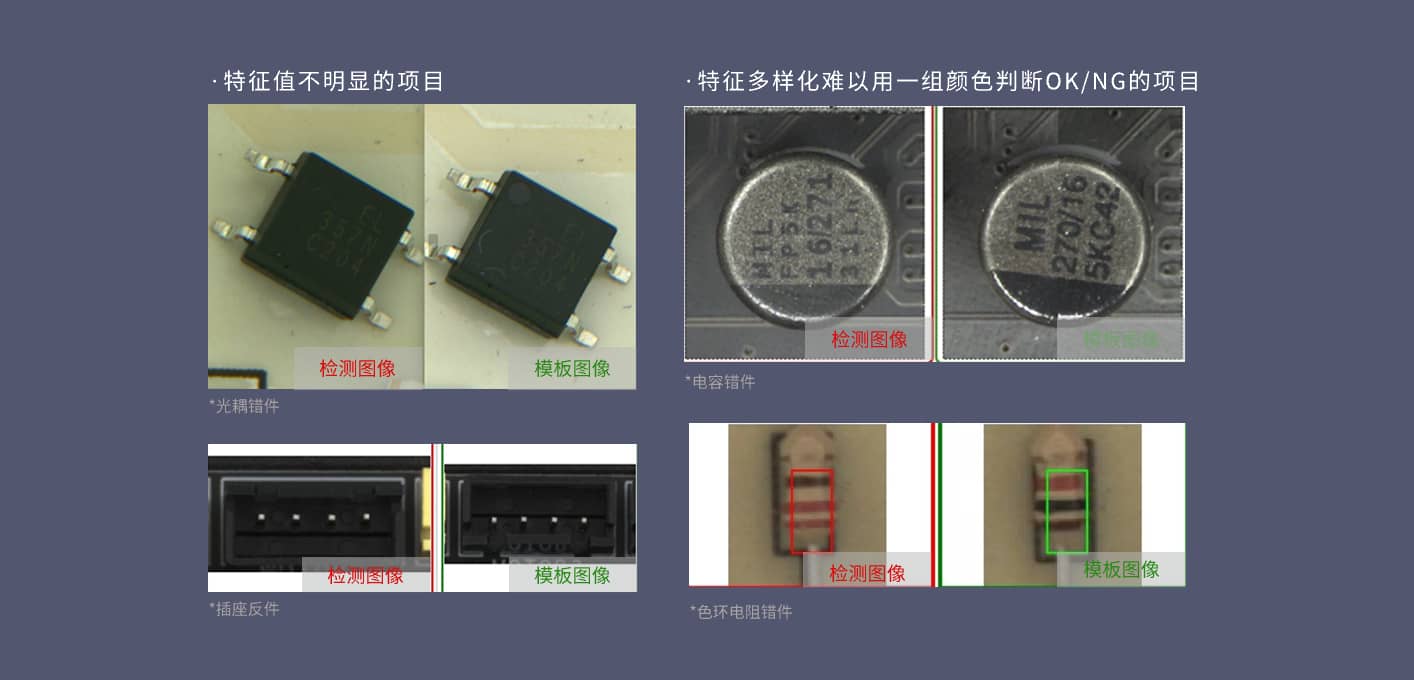

Traditional AOI has poor generalization capability for many defect types, which can cause escapes and false calls during the inspection.

Product quality and reliability are critical competitive advantages. To produce defective products will affect the company's reputation.

Solution

"AI+AOI". One-click Programming. Intelligently judge the defects.

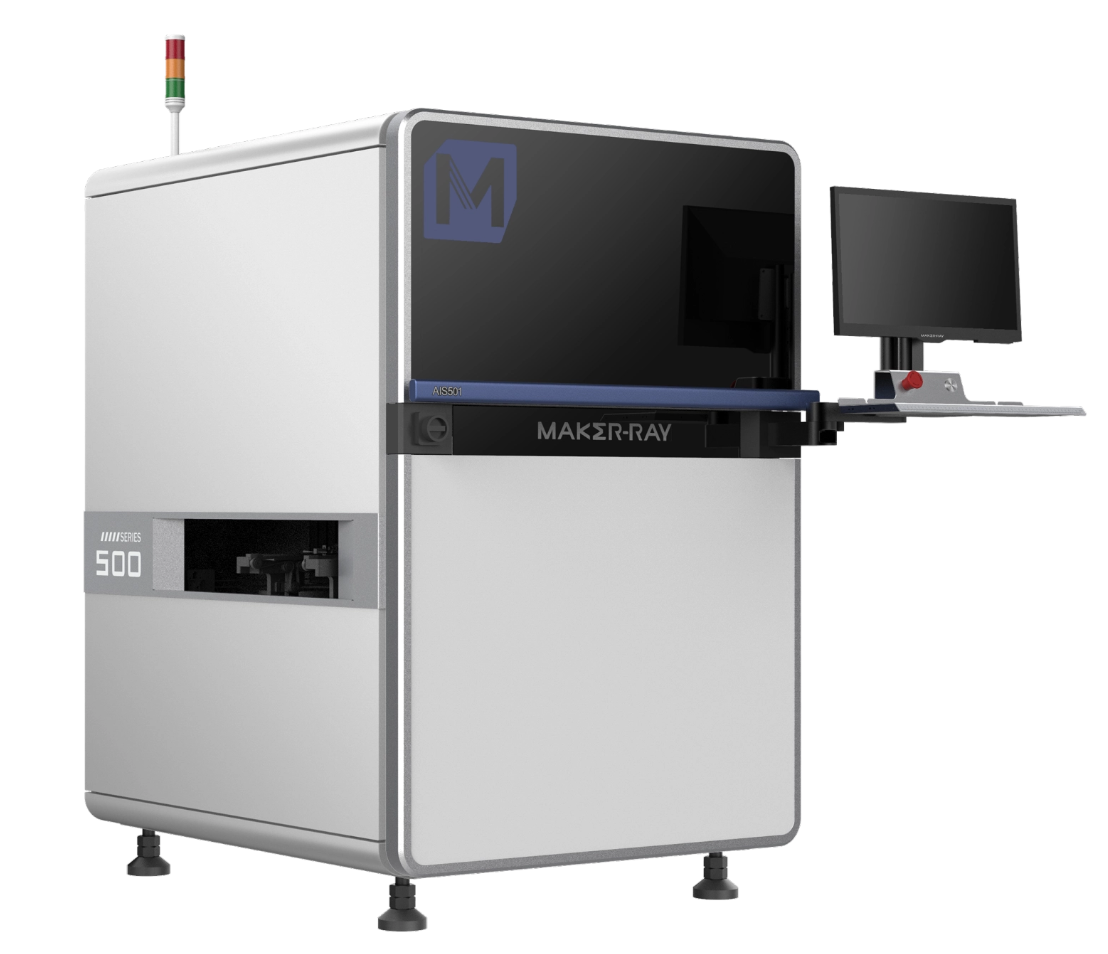

Double-sided AOI - AIS501-L

01

AI Intelligent Programming

One-click component and solder searching intelligently identify and match related algorithms and parameters.

02

Stable defect detection

Covering more than 90% of component solder joints, stable detection of various defects

03

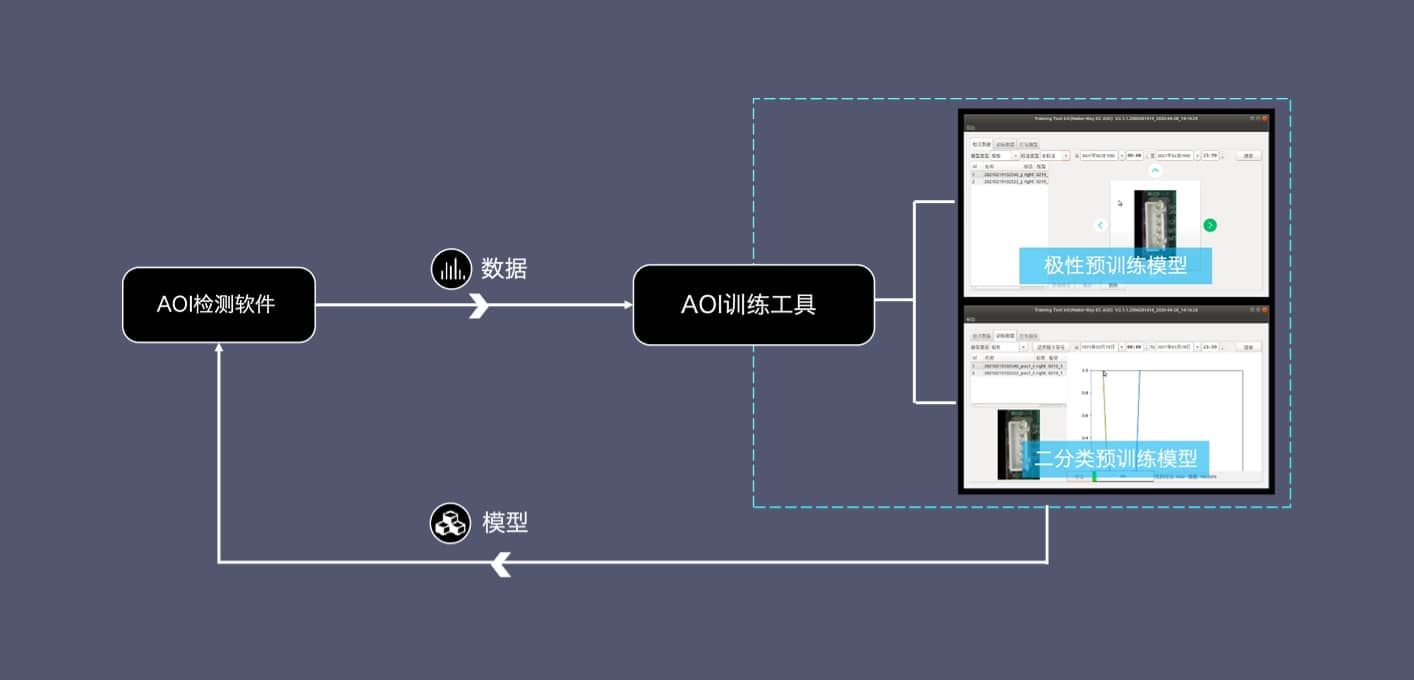

AI continuous training

Supports autonomous training on the machine side to improve detection capabilities

Solution Advantages

"AI+AOI", one-click programming, intelligent judge the defects

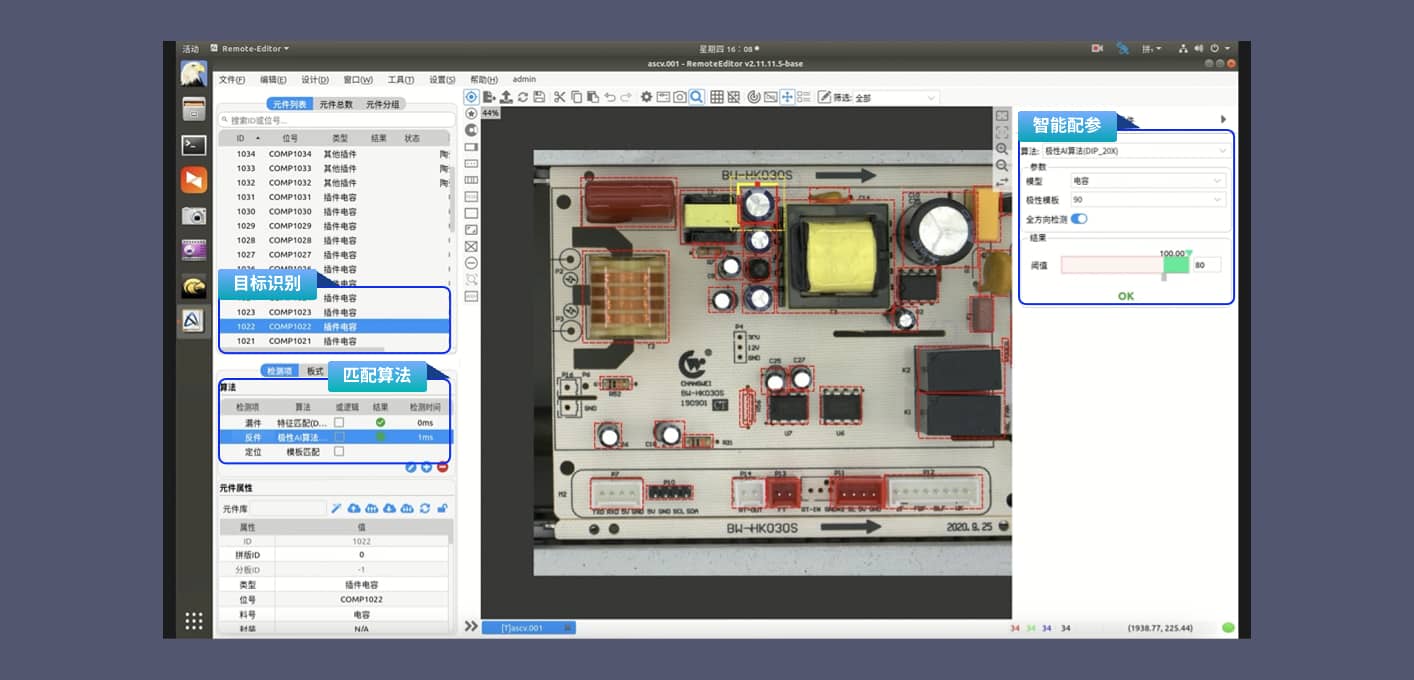

Based on an AI deep learning algorithm, a one-click search for components and solder joints, intelligent identification of matching parameters, and one-click intelligent programming improve engineers' programming efficiency and keep up with production efficiency even with frequent line changes.

Based on the model trained with big data, tens of thousands of features are extracted in multiple dimensions, compatible with fuzzy and complex situations such as component deviation, capacitor skew, solder joint morphology change, similar colors, etc., to meet the detection needs of different scenarios in the proofing industry.

The machine can conduct AI training independently, allowing it to quickly learn new components, special components, and solder joints of different shapes, continuously iterate recognition capabilities, and improve detection capabilities.

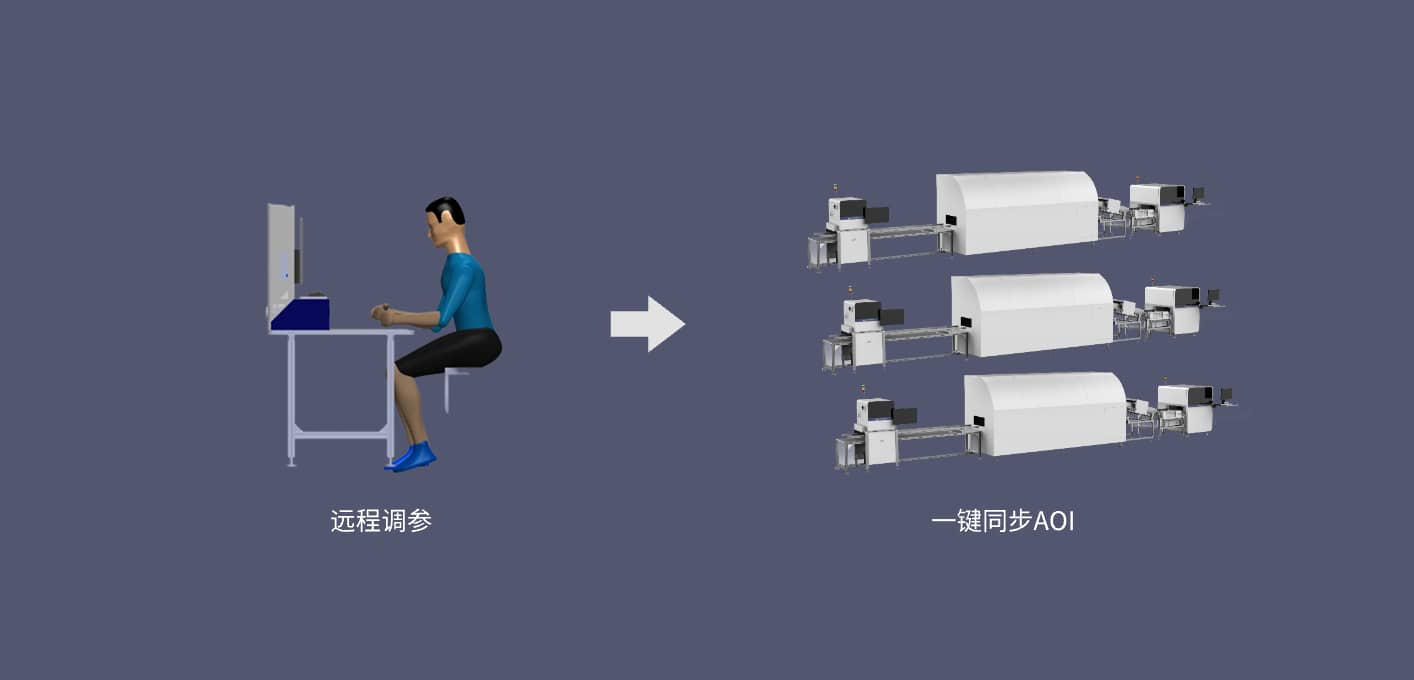

It supports offline programming and remote parameter adjustment. When writing a new program, the production line does not need to be shut down. It is more efficient and convenient to change lines after minor batch proofing.

Customers

They all chose Raychen AOI