Inline PCBA double-sided optical inspection

AIS50X

Both sides simultaneous detection, for product quality escort

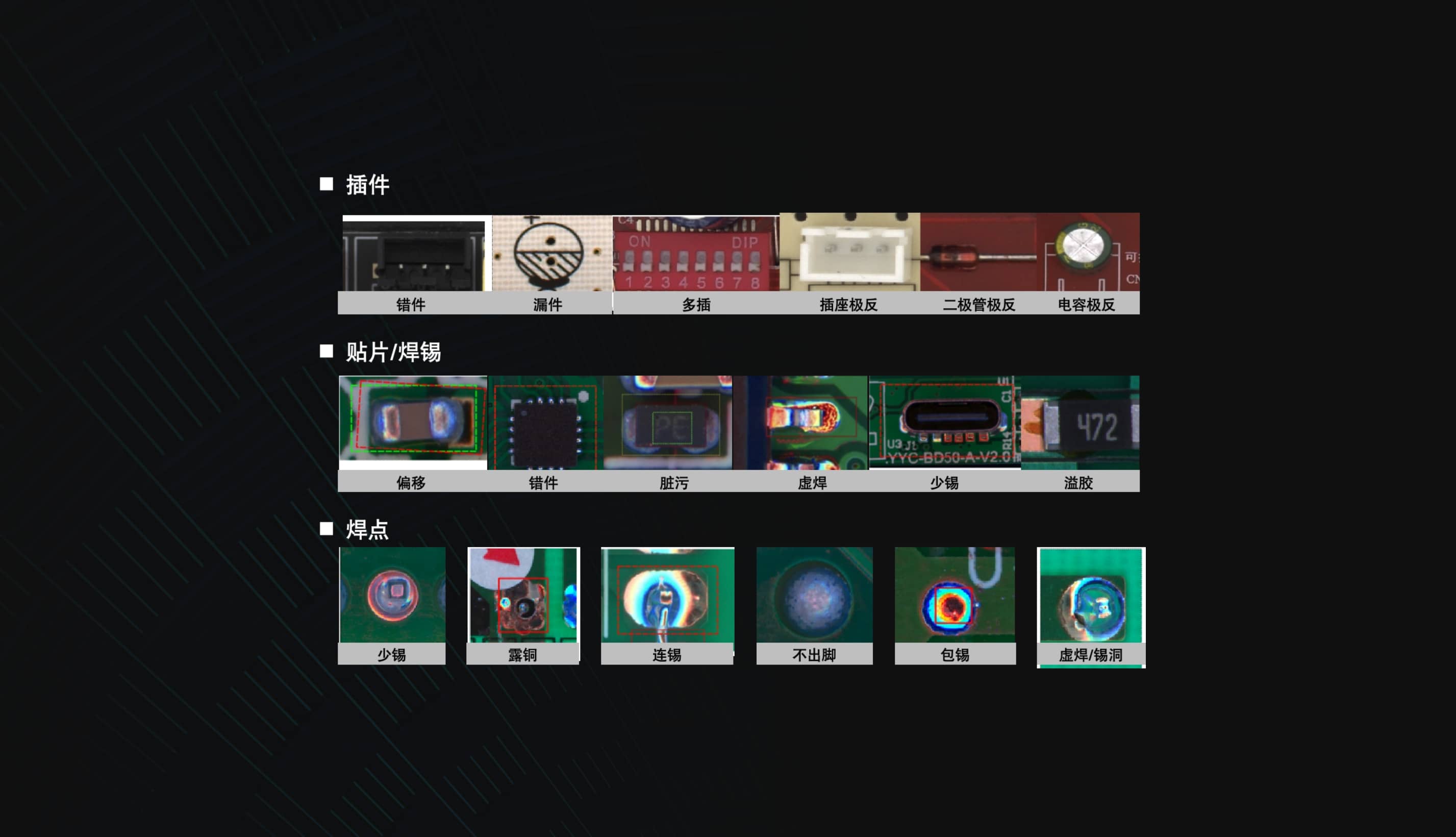

Multi-dimensional extraction of tens of thousands of features, bad detection ability

Special research light source and algorithm to meet the needs of special device detection

Final inspection after reflow soldering, after DIP wave soldering, or before packaging

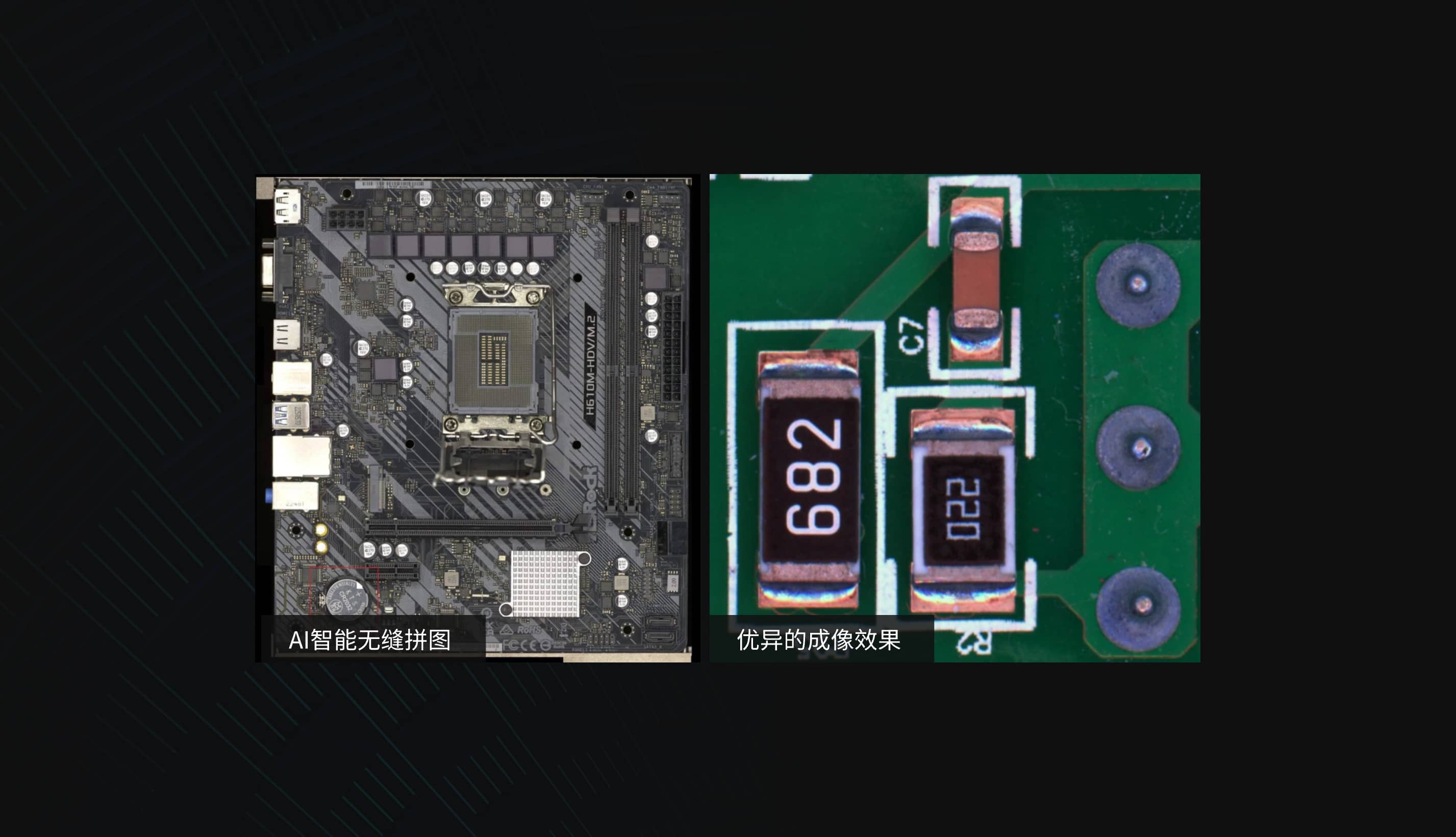

Specially developed light source system, better imaging effect

Independently developed multi-channel light source, compatible with devices, patches, solder joints and other different detection items, effectively improve the image saturation and brightness. Combined with AI intelligent seamless jigsaw technology, shooting stitching is more natural.

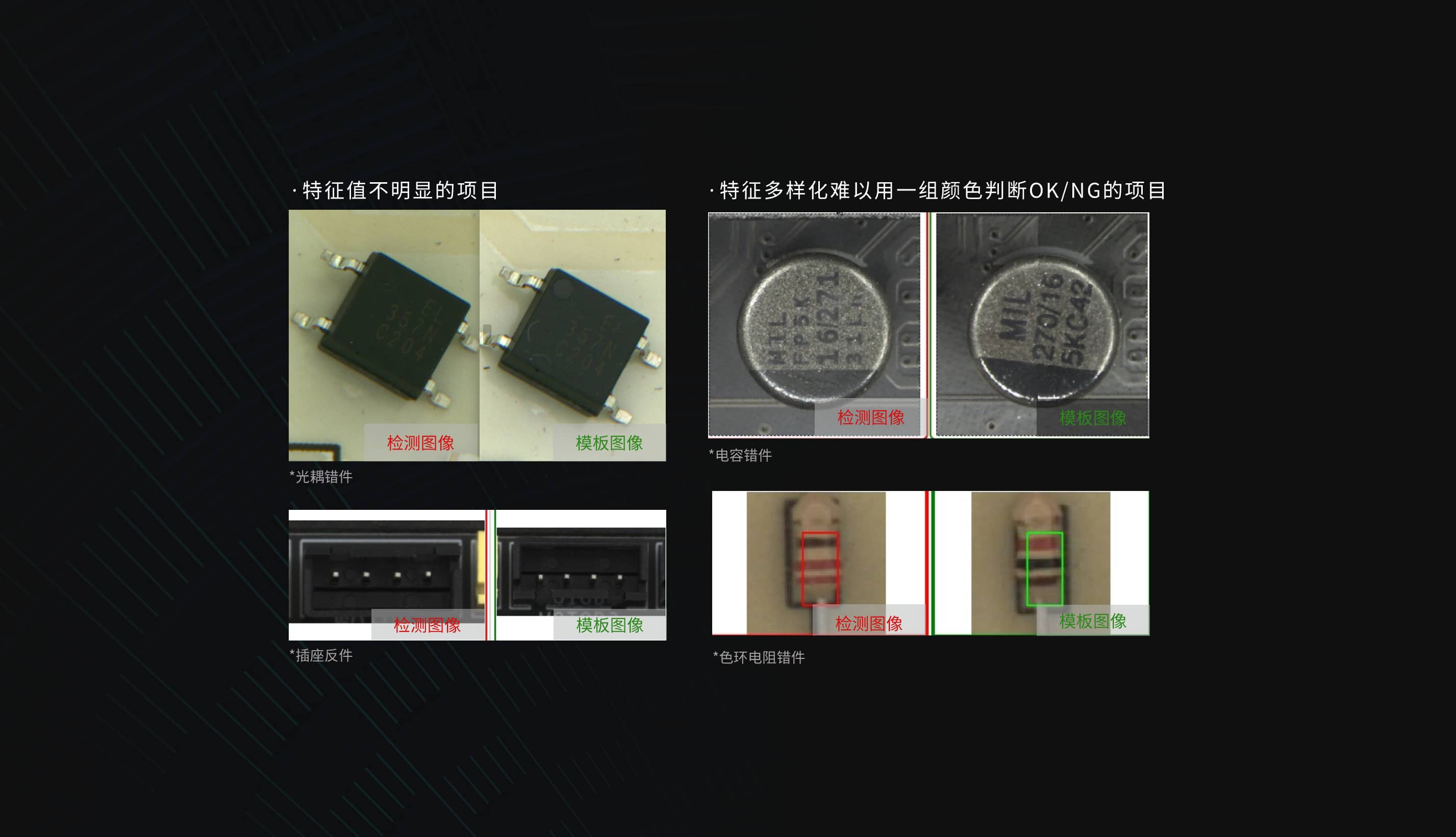

Strong ability to detect and identify complex projects

The model based on big data training is compatible with complex conditions such as device deviation, capacitor skew, solder joint shape change, similar color, irregular arrangement of devices, etc., and has strong detection ability.

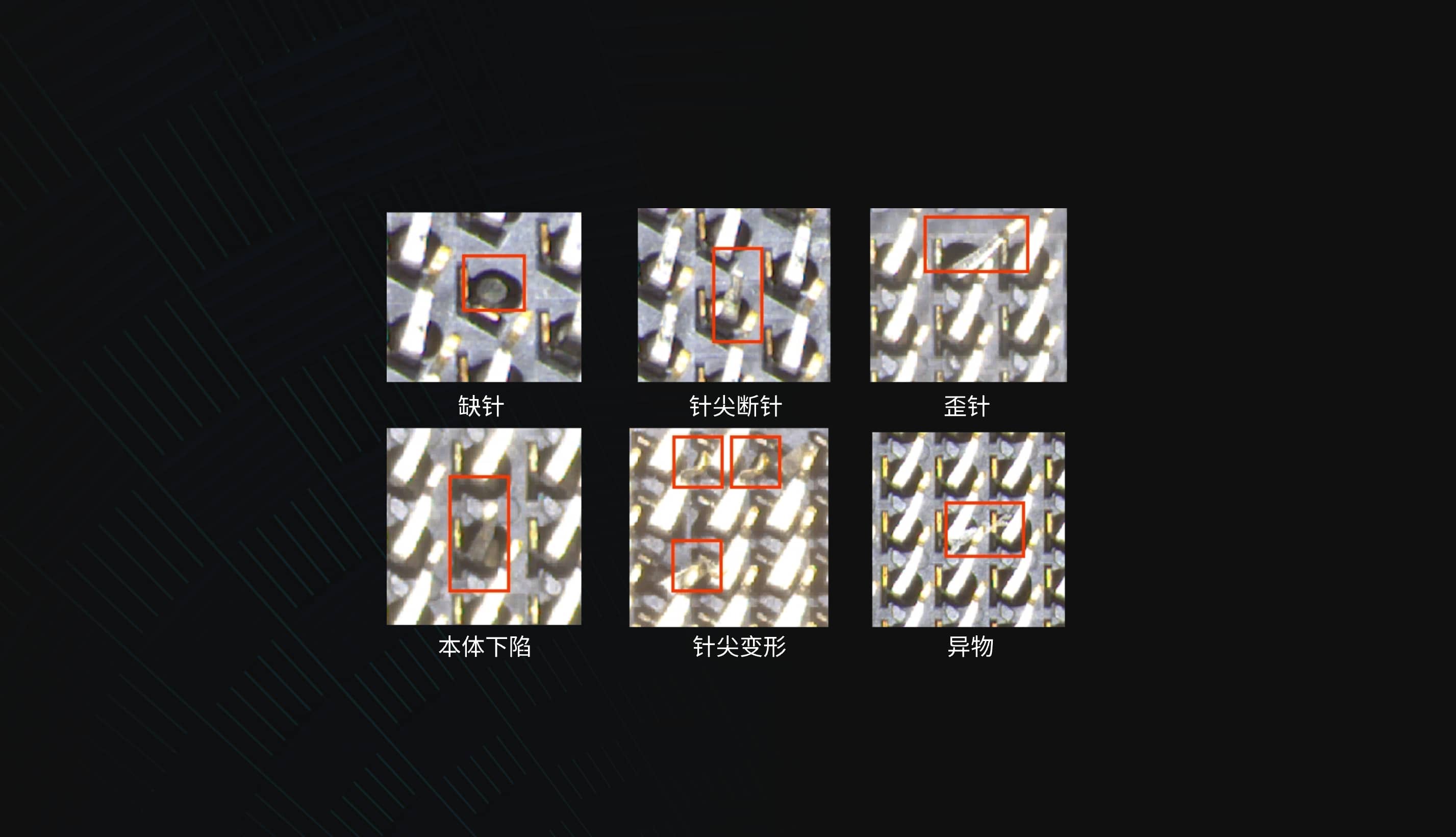

Special research CPU pin matching algorithm, strong detection ability

Special light source to improve the pin imaging effect, combined with the CPU pin matching algorithm, 1 minute to complete the entire CPU pin programming, covering of bad type detection, support the pin point, and body Bad detection of skew, fracture, foreign body, sinking, deformation, missing needle.

Inspection case

Specification