Power storage

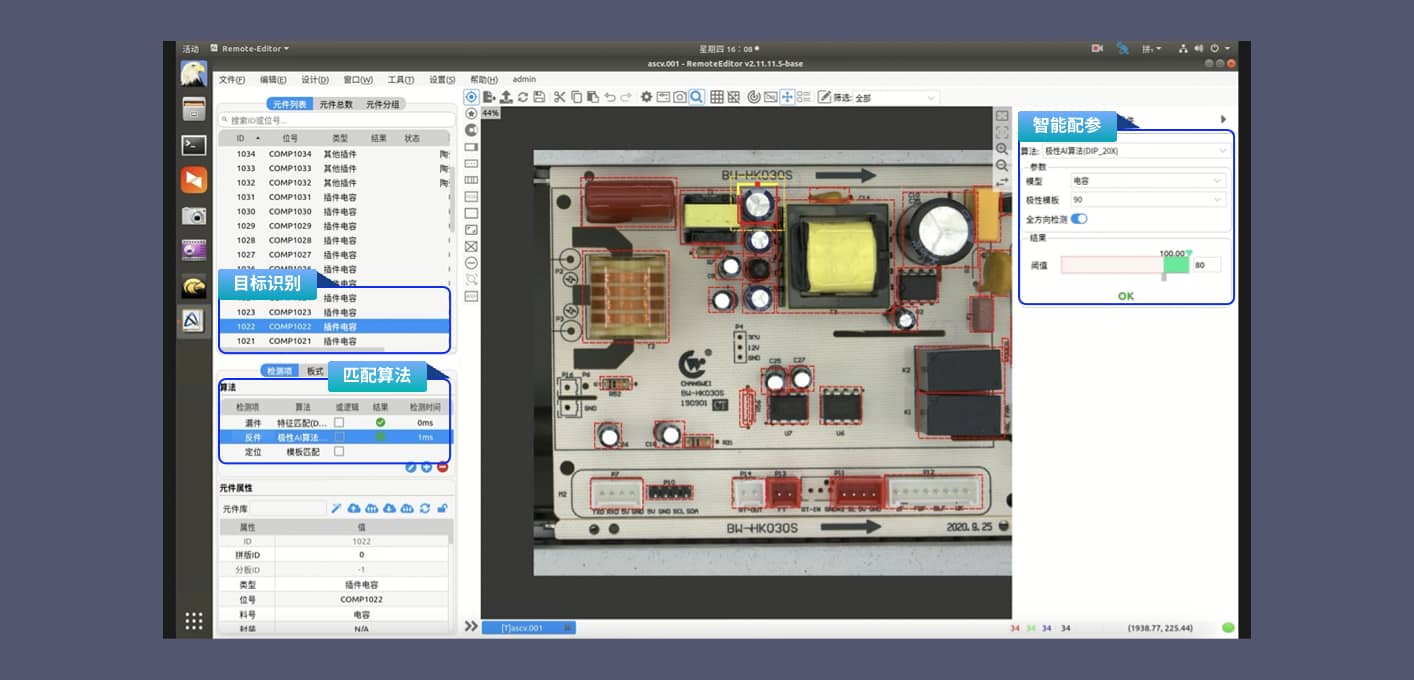

Intelligent programming for stable detection, simultaneous detection and real-time calculation

Industry pain points

Strict process requirements and the cost of defective products remain high.

Power storage has extremely high safety requirements. A small defect may lead to serious consequences, such as battery short circuits and explosions.

A large power board has many components, which is inefficient and prone to missed inspections during manual visual inspection.

Power products' materials and process costs are high, and the cost of defective losses is high, wasting corporate resources.

Solution

Intelligent programming for stable detection, real-time calculation for inspections of both sides

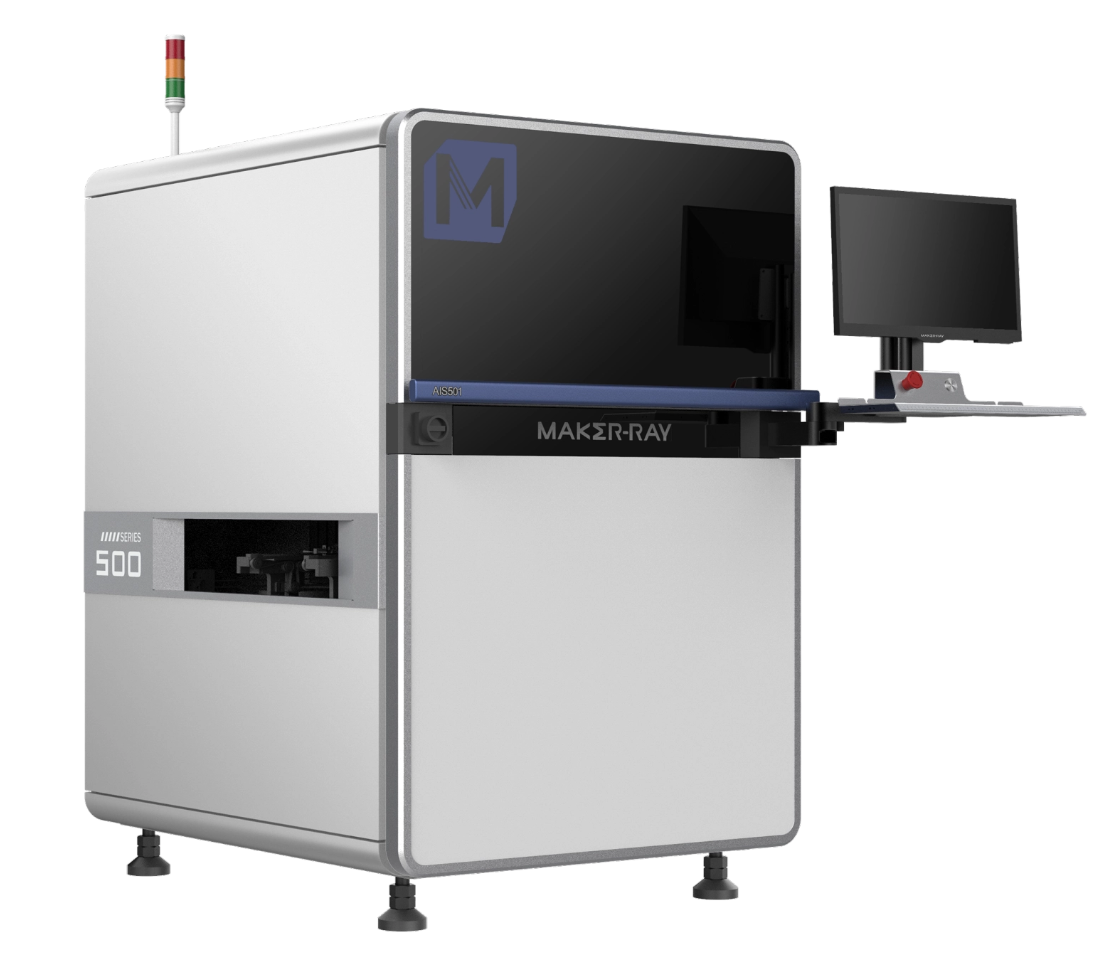

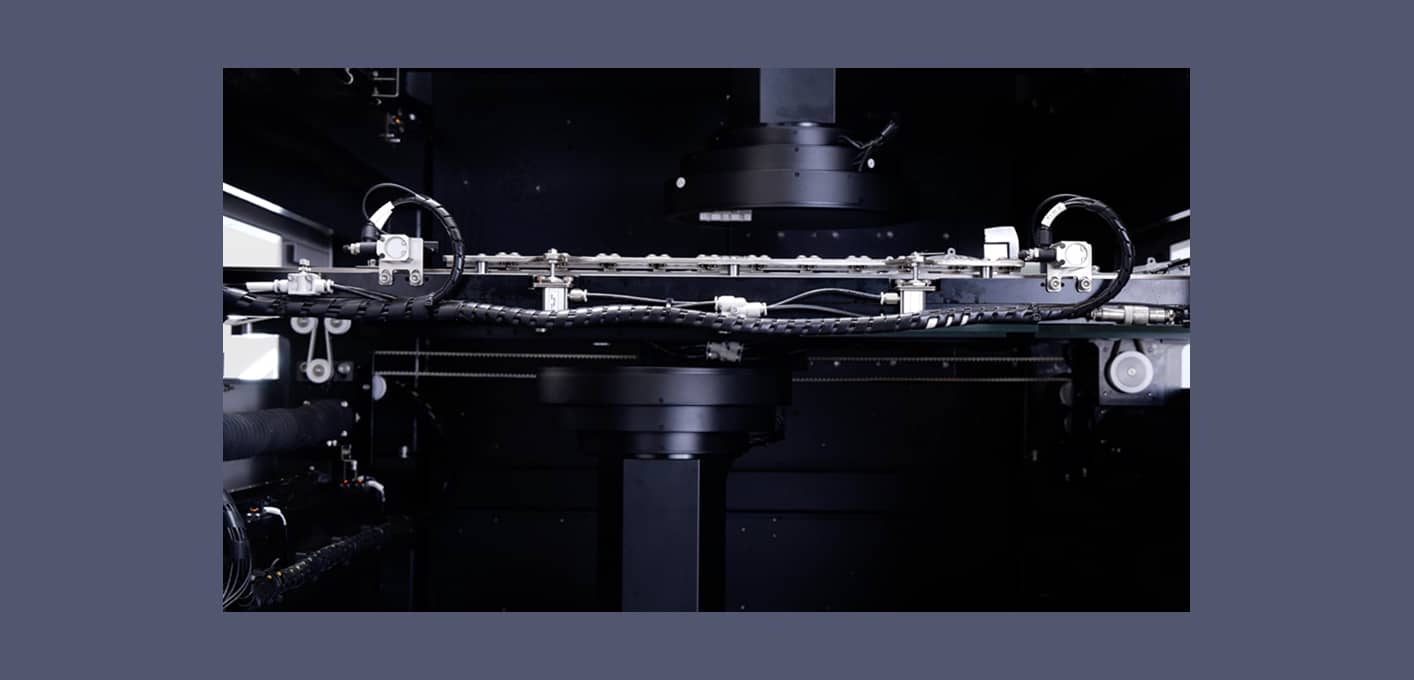

Double-sided AOI - AIS501-L

01

Large board mode

The double-sided AOI in large board mode meets the detection requirements of large power storage boards

02

Multi-scenario application

Can be applied after reflow oven in SMT line, post-wave soldering and final inspection before packaging

03

AI intelligent programming

AI simplified programming, an intelligent judgment of defects

Solution advantages

Intelligent programming for stable detection, real-time calculation for inspections of both sides

One-click selection can automatically identify trained components and solder joints, support intelligent parameter adjustment, significantly improve programming efficiency, and meet the needs of high-mix, low-volume line changes.

Based on deep learning algorithms, it has excellent and intelligent recognition capabilities. It can extract complex inspection items and subtle features, improving detection accuracy.

Double-sided top and bottom asynchronous image capturing, real-time inspection, automatic assigning of inspection paths, and improving inspection speed.

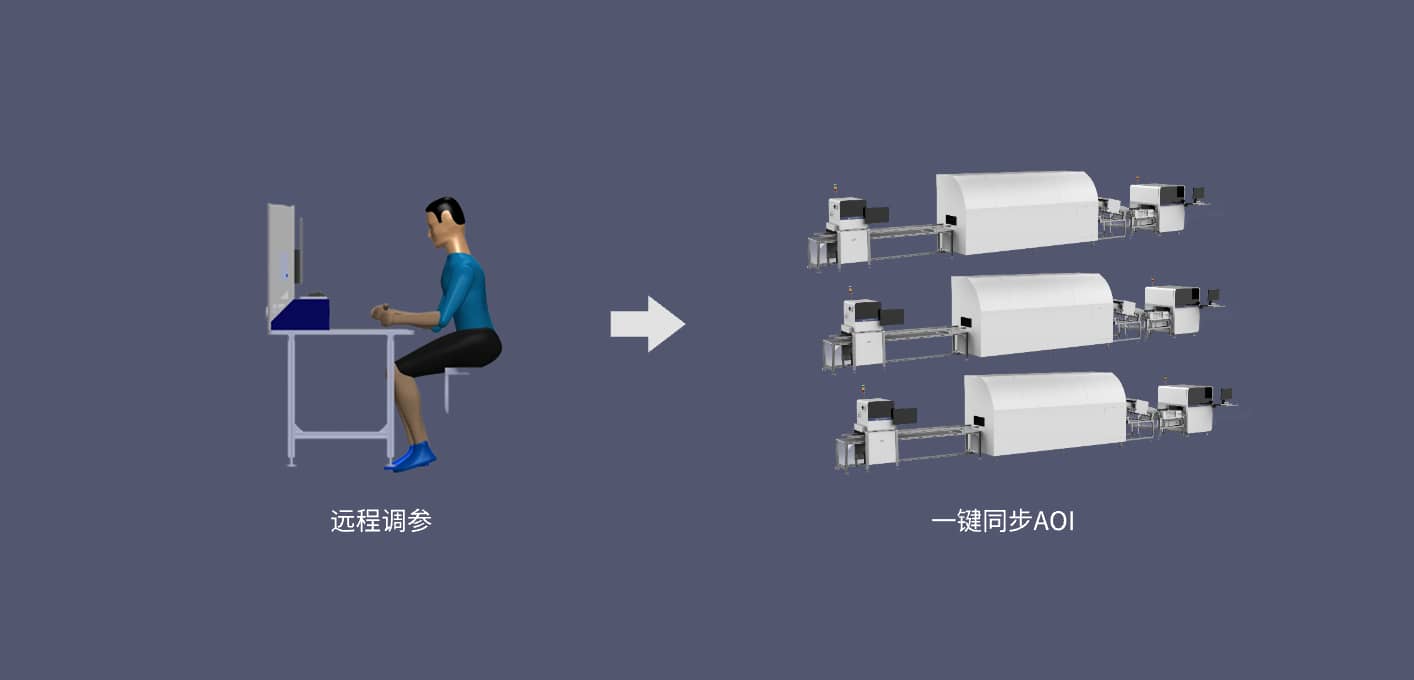

It supports remote parameter adjustment. When fine-tuning the program parameters, it can be adjusted synchronously in real-time without stopping the production line.

Customers

They all chose Raychen AOI