New energy

Full inspection coverage over a 2-meter-long board helps customers reduce costs and increase efficiency.

Industry pain points

Strict process requirements and high cost of defective loss happen on battery protection boards.

The battery protection board has strict process requirements, but the existing detection effect is poor, and there are blind spots and missed detection.

The soft and long battery protection board is easy to expand, shrink, wrap, and deform, resulting in positioning deviation and many false positives.

The battery protection board is expensive and difficult to repair. The defective products will lead to increased production costs and a tremendous waste of resources.

Solution

Full inspection over 2 meters, helping enterprises reduce costs and increase efficiency

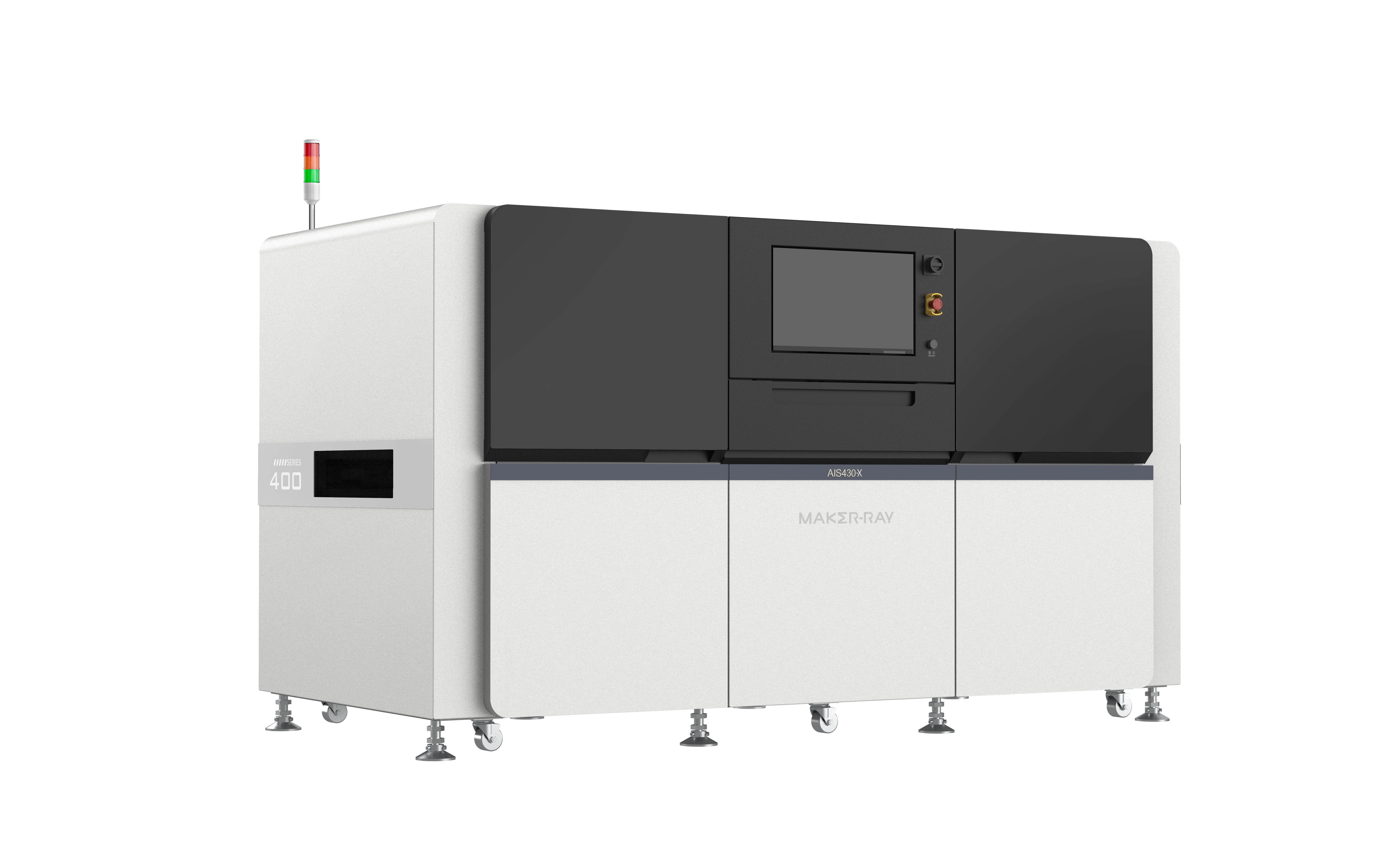

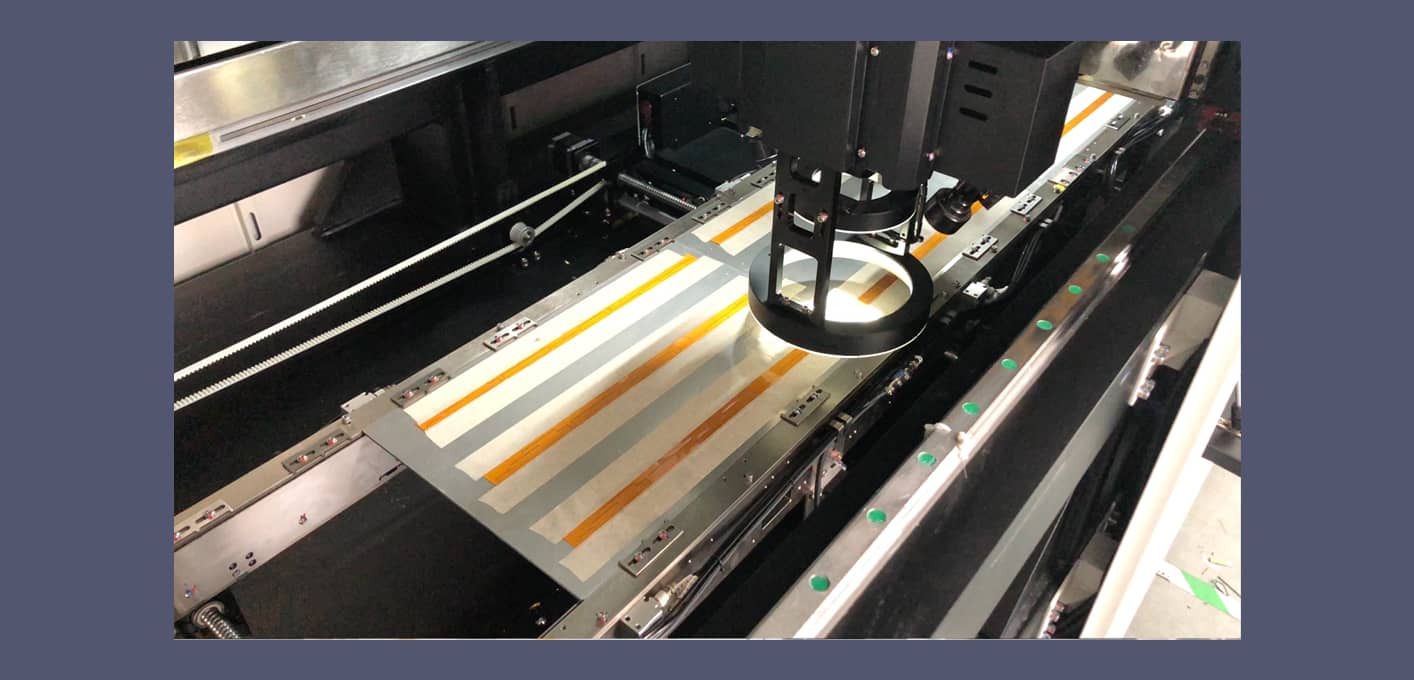

3D AOI for long PCBA - AIS430-X

01

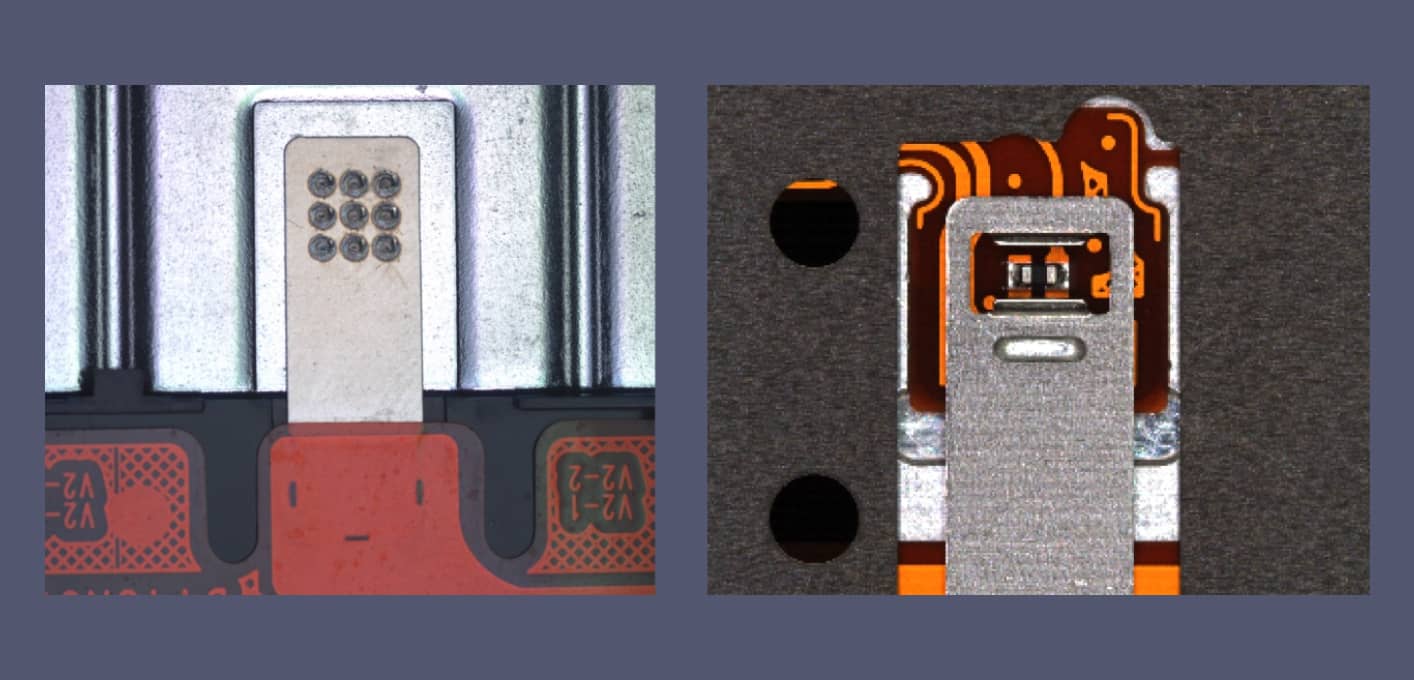

3D multi-angle projection

3D multi-angle projection and dedicated light source truly restore the board image

02

AI algorithm

Intelligently identify different shapes and types of components and solder joints, improve production efficiency and detection accuracy

03

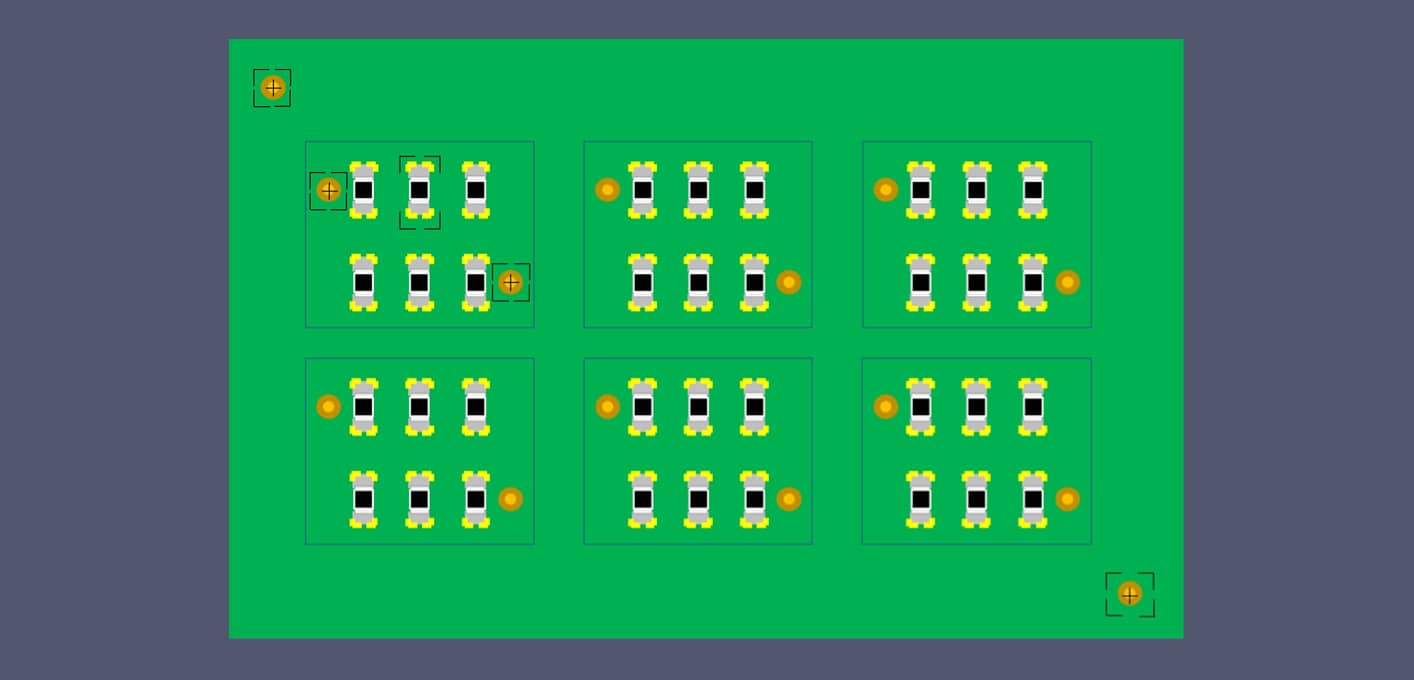

High-accuracy positioning

Improve the positioning accuracy of flexible printed circuits (FPC) and reduce the false call rate

Solution Advantages

Full inspection over 2 meters, helping enterprises reduce costs and increase efficiency.

Using multi-angle projection technology to integrate multi-frequency stripe structured light, the board image is highly restored, eliminating the 3D imaging deformation caused by surface deformation, overexposure or dark imaging, and shadow occlusion.

Using a multi-level positioning method of global marker + panel marker + local marker + component precision positioning to compensate for the curved surface of the soft board, the positioning accuracy is <1 pixel, which greatly improves the positioning accuracy.

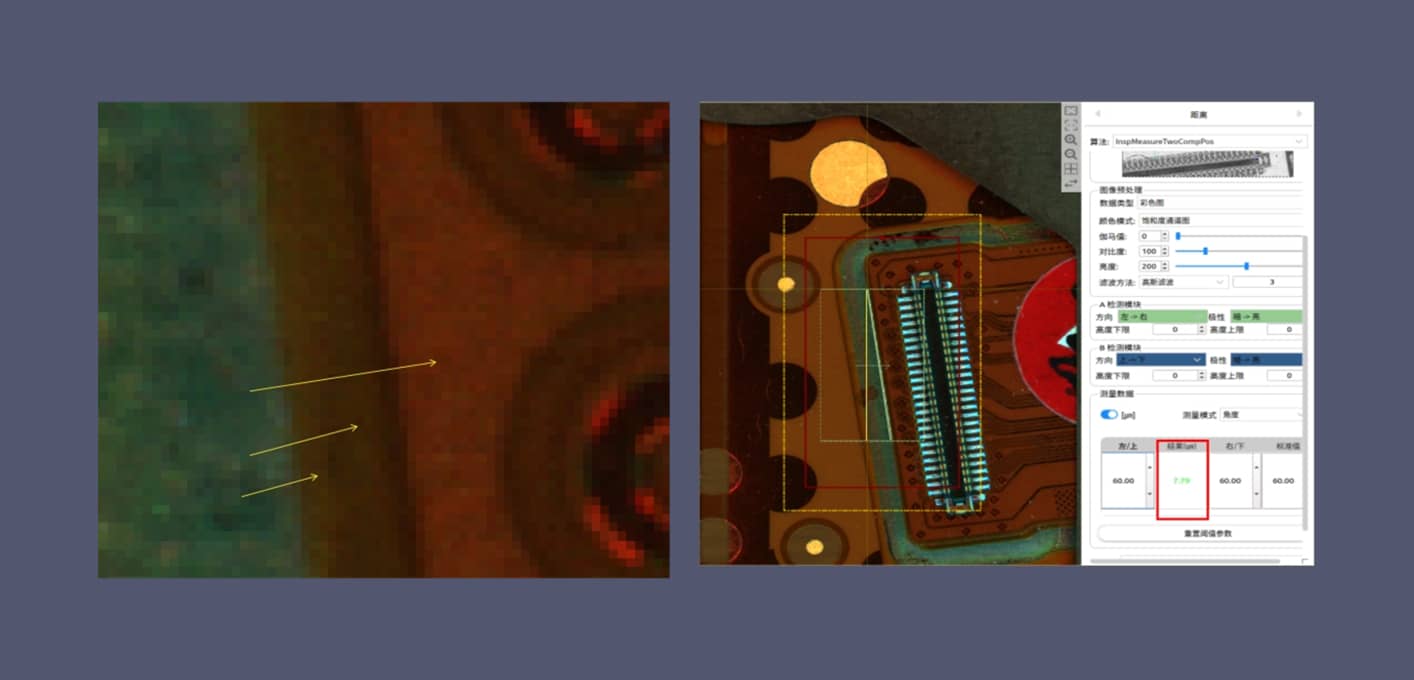

Using the linear angle algorithm to quickly find the edge of the object, calculate the component angle offset, and visualize the offset value to solve the problem of inaccurate edge positioning interfering with angle measurement.

The combination of direct linear motor drive and high-resolution grating ruler can reach a maximum speed of 1-2m/s. Using a large-format lens one-section detection to reduce the lens start-stop movement time and achieve more efficient quality control.

Customers

They all chose Raychen AOI